Richard Becker now living in Sun City Summerlin, Las Vegas, NV, has been taking pictures for the local Link Magazine. The Link is published monthly and is delivered to some 12,000 homes in Sun City Summerlin. The Link June 2020 issue published an article on Richard. The very nice article was written by our Executive Director Mitzi Mills. You can read the article by clicking on the line below and going to Pages 34-36.

http://www.suncitylink.com/uploads/1/0/3/9/103913400/june-2020-link-for-web.pdf

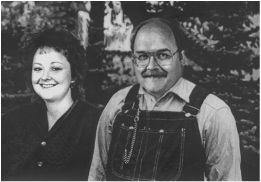

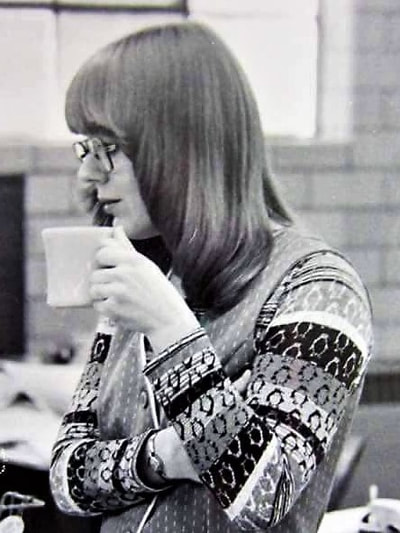

The photo below was taken of Grace Fisher 5-26-22. She now lives at the Sumerset Assisted Living in Minot.

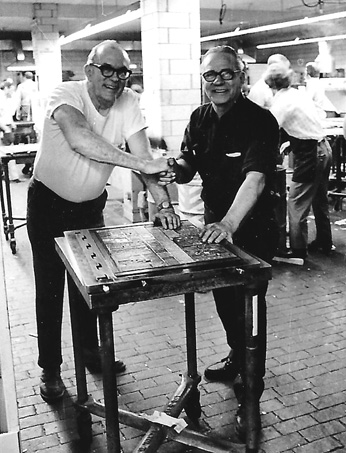

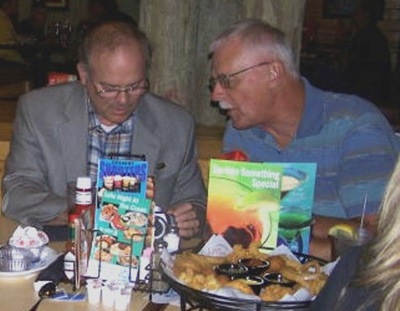

A Few of the Old MDN Boys Got Together for Coffee in July 2022

Richard and Bob worked together at the MDN from 1965 on . . .

Some of My Memories While Working At The Minot Daily News

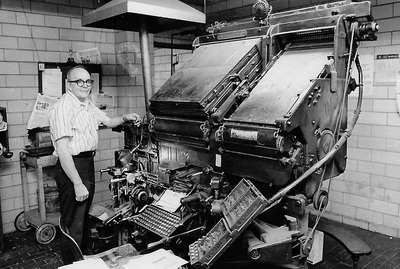

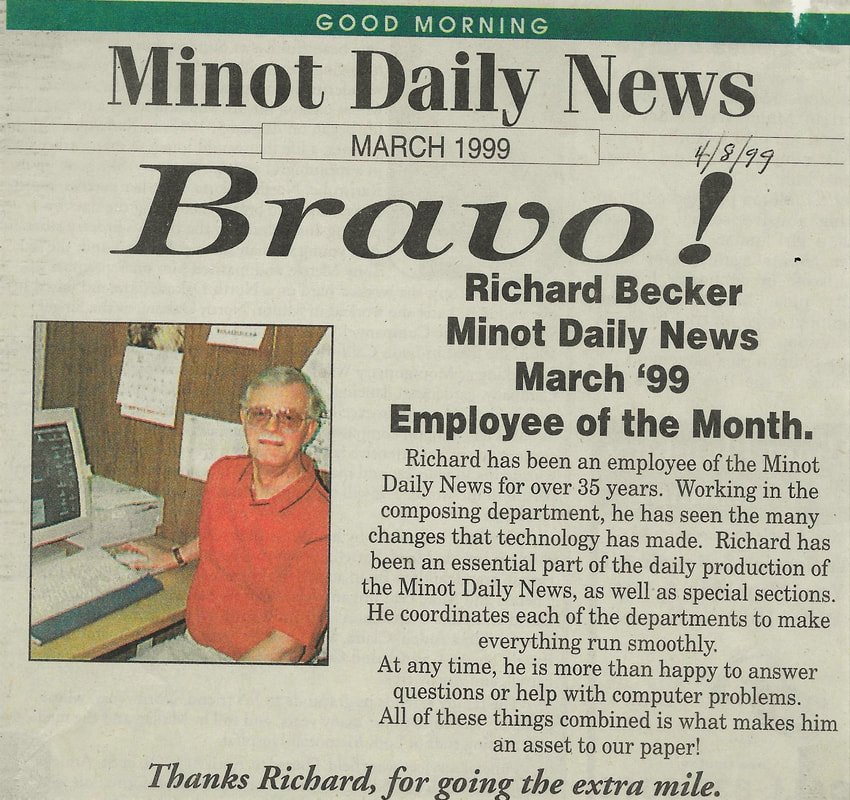

I started working at the MDN June 1, 1964, in the composing room in the hot metal days. I resigned my position as Production Systems Supervisor Oct. 9, 1999. This was my first full time job after one year at college. I held a number of offices with the International Typographical Union (ITU). I was very proud to work for a Minot family owned business.

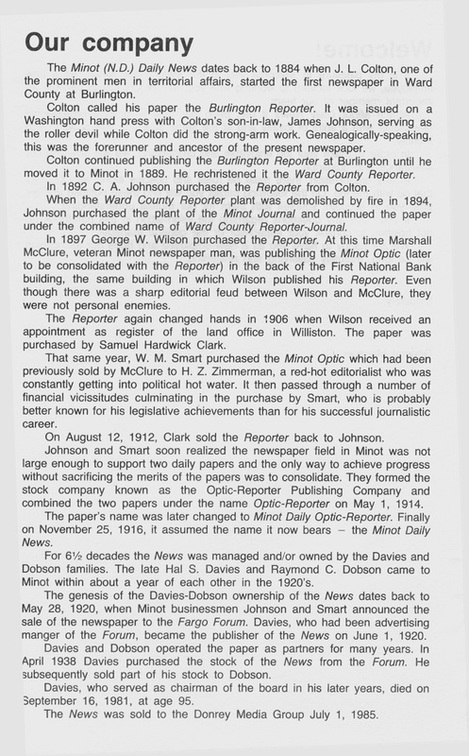

I worked with some very enjoyable and not so people. We had some very interesting parties and picnics. The hot metal days were very hard days of producing the paper. Then came the stressful computer days. To the left is some history of the MDN.

I've selected a few photos below of my hundreds of photos collected over of the years. Make sure you scroll WAY DOWN to the bottom to view all the photos. View each photo by clicking on it. You can always contact me at:

[email protected]

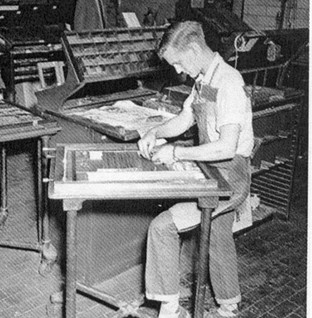

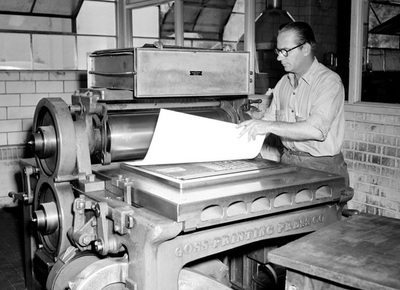

Producing the Minot Daily News the Hot Metal Way

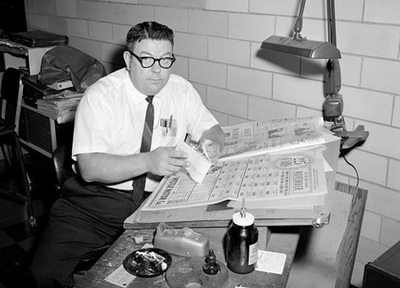

The advertising salesperson from the Minot Daily News meets with his client to decide on the size of ad he wants to appear in the paper and the day to run it. The salesperson after visiting with the business person takes the information and puts together the ad on a layout sheet back at the Minot Daily News. This layout sheet goes to the composing room. Here a composing room member called the ad markup person decides the size of type to be used for the ad. He marks the type size on the layout sheet and gives the layout to the linotype operator. The type for the ad is either set on the linotype or someone operating the Ludlow machine. The artwork for the ad is made from a mat that hot metal is poured on in the press room. When the type has been set for the ad it is placed on a galley. (The galley is a steel tray that comes in varies lengths and widths used to hold composed type.) An ad man in the composing room takes the galley of type and the cuts (cast artwork) from the press room and begins to build the ad. After finishing the ad it is proofed and given to the salesperson to check and show the client for changes.

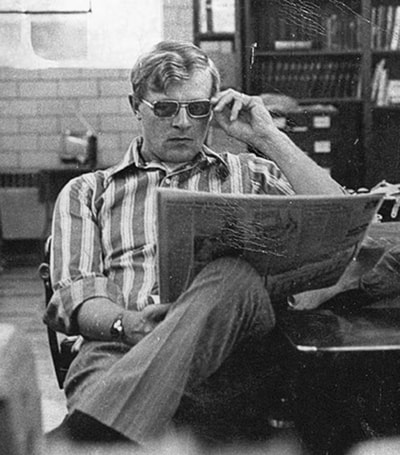

A reporter in the news room at the Minot Daily News sits at his desk going over his notes from an interview or from covering an event. After getting his notes in order he begins to type his story on a manual typewriter. After completing the story it is given to an editor. The editor decides what day the story will appear in the paper and what page. Now the editor types out a headline for the story. He also decides if a photo is to accompany the story in the paper. If so he types up some cut lines for the photo. He also decides the size of the photo. If a photo is to appear with the story the photographer develops the film for the editor to pick which photo to use with the story. The negative is now taken to the photo engravers in the basement of the Minot Daily News. Here through a process an engraving of the picture is made and placed on a block of wood to make it type high and delivered to the makeup person in the composing room. The headline, story and cut lines are taken to the composing room to begin the process of converting to type. The story is picked up by a teletype operator to begin typing the story over on a teletype setter. As the teletype operator strikes the keys holes are punched in the paper tape. The tape of paper is about an inch wide and comes on big rolls fed into the teletype setter. When the operator completes typing the story it along with the tape is given to the linotype operator. Now the tape is fed into a machine that’s placed on a linotype to handle the tape. Each hole on the tape is matched to a character on the linotype and is now made into a line of type. When the tape stops the story is complete in lines of hot metal now cooled to metal lines. The linotype operator dumps the story of lines on a galley. A makeup man now takes the galley and places the headline and cut lines with the story at the front of the galley. Then a proof is taken of this galley. The original story and the proof are handed to a proof reader in the news room for proofing. After the story is proofed and OK’ed the type is placed in a chase along with the ads for that page. (The steel chase is a four sized frame the size of a page in the paper.) An editor tells the makeup person which page and the position on the page the type is to be placed. After all the type and ads are on the page a page proof is taken for the news room proof readers to check over for the last time. Sometimes a page proof is given to the advertising department to proof the ads.

After the page has been OK’ed the page is rolled into the press room. Here a press man takes a moist paper mat and places this on the page full of type and ads. This page and mat are run under a steel roller under high pressure. The mat now contains indentations of the type and ads of the page. This mat is placed on a holding device and hot metal from a large hot metal pot is run onto the mat. Now the characters from the original page become raised formations on this metal plate ready to be placed on the cylinder press. When the press has all the pages placed in their correct place the paper is run off. The papers as they come off the press are sent by a conveyor to the mail room for stamping. Here a mail room member sits at a labeling machine and stamps the subscribers name on the paper. Now the papers are grouped and placed into large bags ready to be delivered to the Post Office. Other papers are readied for the local carriers to deliver to each resident.

During the hot metal days the paper went to press around noon for the final printing of the paper. This was referred to as an afternoon paper.

I worked with some very enjoyable and not so people. We had some very interesting parties and picnics. The hot metal days were very hard days of producing the paper. Then came the stressful computer days. To the left is some history of the MDN.

I've selected a few photos below of my hundreds of photos collected over of the years. Make sure you scroll WAY DOWN to the bottom to view all the photos. View each photo by clicking on it. You can always contact me at:

[email protected]

Producing the Minot Daily News the Hot Metal Way

The advertising salesperson from the Minot Daily News meets with his client to decide on the size of ad he wants to appear in the paper and the day to run it. The salesperson after visiting with the business person takes the information and puts together the ad on a layout sheet back at the Minot Daily News. This layout sheet goes to the composing room. Here a composing room member called the ad markup person decides the size of type to be used for the ad. He marks the type size on the layout sheet and gives the layout to the linotype operator. The type for the ad is either set on the linotype or someone operating the Ludlow machine. The artwork for the ad is made from a mat that hot metal is poured on in the press room. When the type has been set for the ad it is placed on a galley. (The galley is a steel tray that comes in varies lengths and widths used to hold composed type.) An ad man in the composing room takes the galley of type and the cuts (cast artwork) from the press room and begins to build the ad. After finishing the ad it is proofed and given to the salesperson to check and show the client for changes.

A reporter in the news room at the Minot Daily News sits at his desk going over his notes from an interview or from covering an event. After getting his notes in order he begins to type his story on a manual typewriter. After completing the story it is given to an editor. The editor decides what day the story will appear in the paper and what page. Now the editor types out a headline for the story. He also decides if a photo is to accompany the story in the paper. If so he types up some cut lines for the photo. He also decides the size of the photo. If a photo is to appear with the story the photographer develops the film for the editor to pick which photo to use with the story. The negative is now taken to the photo engravers in the basement of the Minot Daily News. Here through a process an engraving of the picture is made and placed on a block of wood to make it type high and delivered to the makeup person in the composing room. The headline, story and cut lines are taken to the composing room to begin the process of converting to type. The story is picked up by a teletype operator to begin typing the story over on a teletype setter. As the teletype operator strikes the keys holes are punched in the paper tape. The tape of paper is about an inch wide and comes on big rolls fed into the teletype setter. When the operator completes typing the story it along with the tape is given to the linotype operator. Now the tape is fed into a machine that’s placed on a linotype to handle the tape. Each hole on the tape is matched to a character on the linotype and is now made into a line of type. When the tape stops the story is complete in lines of hot metal now cooled to metal lines. The linotype operator dumps the story of lines on a galley. A makeup man now takes the galley and places the headline and cut lines with the story at the front of the galley. Then a proof is taken of this galley. The original story and the proof are handed to a proof reader in the news room for proofing. After the story is proofed and OK’ed the type is placed in a chase along with the ads for that page. (The steel chase is a four sized frame the size of a page in the paper.) An editor tells the makeup person which page and the position on the page the type is to be placed. After all the type and ads are on the page a page proof is taken for the news room proof readers to check over for the last time. Sometimes a page proof is given to the advertising department to proof the ads.

After the page has been OK’ed the page is rolled into the press room. Here a press man takes a moist paper mat and places this on the page full of type and ads. This page and mat are run under a steel roller under high pressure. The mat now contains indentations of the type and ads of the page. This mat is placed on a holding device and hot metal from a large hot metal pot is run onto the mat. Now the characters from the original page become raised formations on this metal plate ready to be placed on the cylinder press. When the press has all the pages placed in their correct place the paper is run off. The papers as they come off the press are sent by a conveyor to the mail room for stamping. Here a mail room member sits at a labeling machine and stamps the subscribers name on the paper. Now the papers are grouped and placed into large bags ready to be delivered to the Post Office. Other papers are readied for the local carriers to deliver to each resident.

During the hot metal days the paper went to press around noon for the final printing of the paper. This was referred to as an afternoon paper.

Sorry that a number of those in the photos below have passed away.

Click on any photo below to view that photo!! You may also right click on any photo.

Click on any photo below to view that photo!! You may also right click on any photo.

Minot Daily News Trivia

Answers are of Former MDN Employees

(Put together by Richard Becker)

Answers are of Former MDN Employees

(Put together by Richard Becker)

|

1. One of the MDN owners seen all the time in a bow tie?

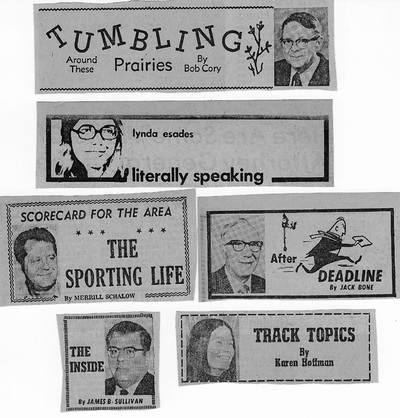

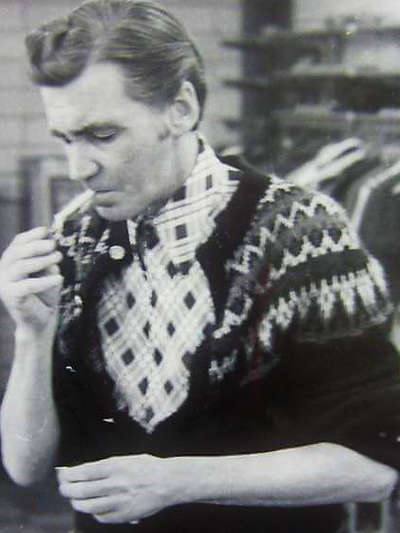

2. Two composing room members from Epswich, SD? 3. Authored a column entitled "Prairie Perspective"? 4. Composing room employee who drove in from Granville each day for years? 5. One of the unmarried owners who owned a house boat? 6. Wrote a column under the name of "Track Topics"? 7. Ran a linotype setting type for ads holding a cigarette? 8. Newsroom employee who smoked a pipe in his early years? 9. Composing room worker always seen in a gray shirt and pants? 10. Single newsroom reporter traveling around NW ND writing long stories for Saturday papers? 11. Composing room worker who rolled his own cigarettes and also smoked a pipe? 12. Worker in the mailing room and his wife Ann ran the switchboard for a short time? |

13. Newsroom reporter always seen in a white shirt and tie?

14. Tall Press room worker always seen with a paper hat? 15. Newsroom writer who made a video of the MDN? 16. Newsroom reporter who authored a column named "Literally Speaking"? 17. Two composing room workers from the Harvey area? 18. Mailing room foreman that had his wife and kids working for him? 19. Composing room worker who served on the Minot City Council? 20. His CB handle was Shutter Bug? 21. Composing room foreman seen in a white t-shirt most of the time? 22. Ran the lunchroom kitchen for many years? 23. Newsroom worker seen with a Camel cigarette in his ear? 24. He worked in the press room and his wife worked in the circulation dept.? 25. If he stopped quick Steve Baker would run into him? |

Answers to "Minot Daily News Trivia"

1. Hal Davis 2. Dave Germain & Pete Mastel 3. Dick Dobson 4. Harold Harmon 5. Hugh Davis

6. Karen Hoffman 7. Les Schley 8. Jack Bone 9. Pete Mastel 10. Leonard Lund

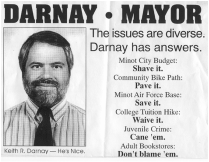

11. Mel Coad 12. Alvin Beck 13. Jim Sullivan 14. Art Hartvikson 15. Keith Darnay

16. Lynda Esades 17. Andy Deck & LeRoy Eberle 18. Joe Pflepsen 19. Dave Germain

20. Bob Petry 21. Jack Brehmer 22. Jean Marks 23. Carl Flagstad

24. Joe Hennes 25. Danny Diego

1. Hal Davis 2. Dave Germain & Pete Mastel 3. Dick Dobson 4. Harold Harmon 5. Hugh Davis

6. Karen Hoffman 7. Les Schley 8. Jack Bone 9. Pete Mastel 10. Leonard Lund

11. Mel Coad 12. Alvin Beck 13. Jim Sullivan 14. Art Hartvikson 15. Keith Darnay

16. Lynda Esades 17. Andy Deck & LeRoy Eberle 18. Joe Pflepsen 19. Dave Germain

20. Bob Petry 21. Jack Brehmer 22. Jean Marks 23. Carl Flagstad

24. Joe Hennes 25. Danny Diego

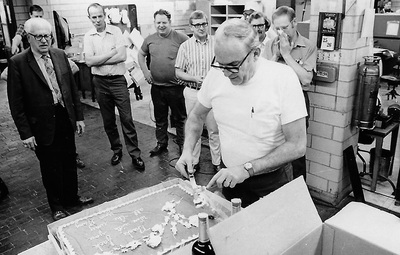

Some of My Good Old Days at The Minot Daily News

|

October 9, 1999 I was gone...after being pushed around I decided to turn my time in and get on with my life. A few people I thought were my friends really turned their backs on me. I find it very hard to forgive them for this back stabbing!!! |

To the left are some of the tools used in the hot type days by the composing room people to put pages together. Can you name these tools? Email your answer at: [email protected] |

Jack, Les and Pete (ITU Local 376) with

Mr. Dobson (owner/publisher) signing union contract

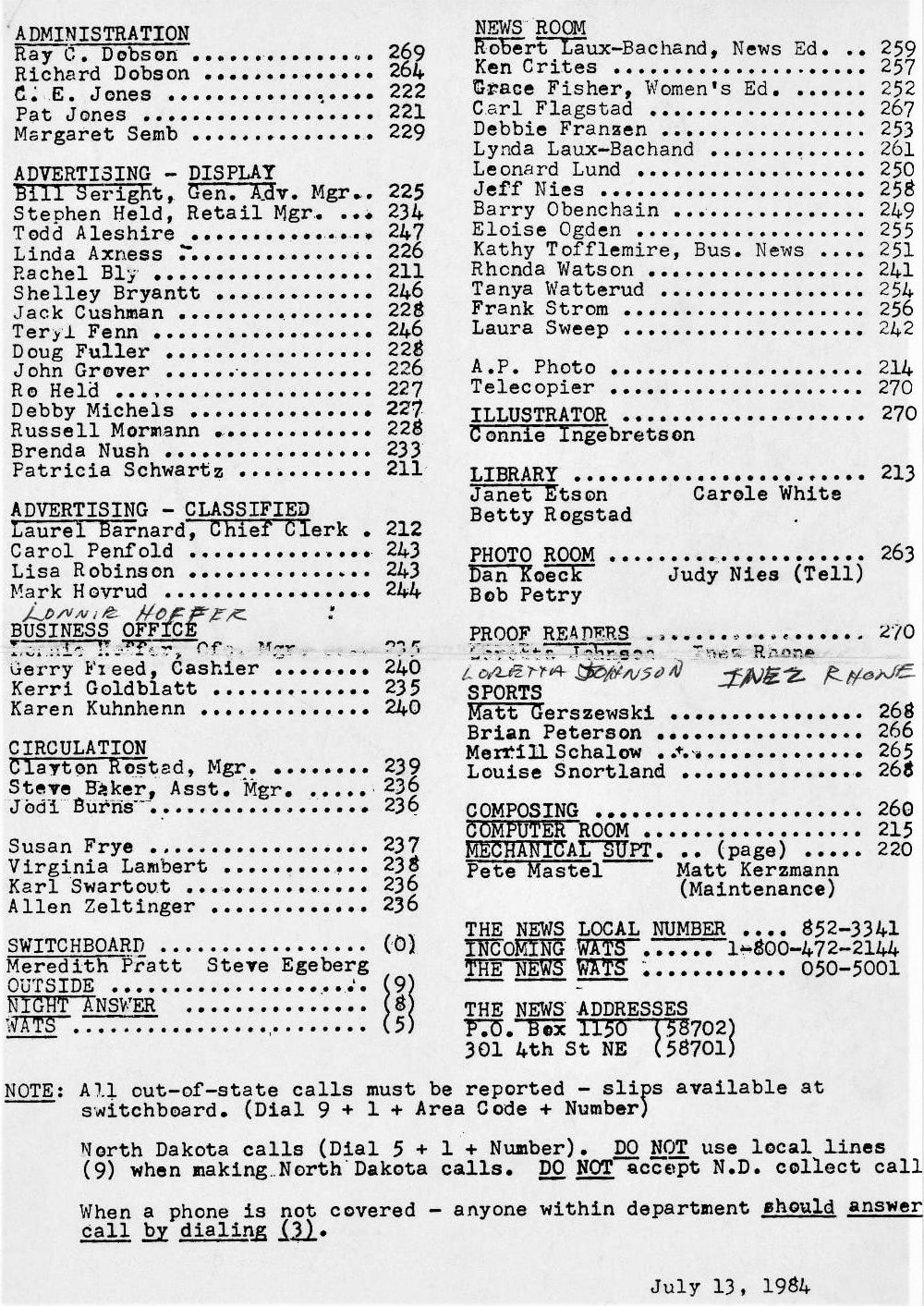

The below names and numbers are provided by former MDN photo man Dan Koeck.

(So many have passed away . . . .I count 21.)

(So many have passed away . . . .I count 21.)